Upholstery Welding for Historic Restoration

In the intricate process of historic restoration, upholstery welding serves as a vital tool for preserving the authenticity and integrity of antique furniture and fixtures. Just as a skilled artisan meticulously weaves together threads to create a tapestry, upholstery welding delicately fuses materials to mend and reinforce cherished pieces of the past.

This article delves into the techniques, materials, and applications of upholstery welding, shedding light on its significance in the meticulous preservation of historical treasures.

The Importance of Upholstery Welding

The importance of upholstery welding lies in its ability to preserve the structural integrity and authenticity of historically significant furniture pieces. Seam strength is crucial to ensuring that the upholstery maintains its form and durability over time. Precision welding techniques are essential for seamlessly integrating new materials with the original structure, ensuring that the historical significance and aesthetic appeal of the furniture are preserved.

When restoring historically significant furniture, maintaining seam strength is vital to prevent premature wear and tear. Upholstery welding reinforces the seams, preventing fraying or unraveling, and thereby extending the lifespan of the furniture. Moreover, precision welding allows for the seamless integration of new upholstery materials while maintaining the original design. This process ensures that the historical authenticity of the piece is upheld, and the structural integrity is preserved for years to come.

Materials and Tools for Upholstery Welding

When considering upholstery welding for historic restoration, the selection of appropriate materials and tools is paramount for achieving precise and durable results.

The following are crucial materials and tools for upholstery welding:

-

Upholstery Materials: Choose high-quality upholstery materials such as leather, vinyl, or fabric that are suitable for welding. These materials should be compatible with welding techniques and capable of withstanding the heat and pressure involved in the welding process.

-

Welding Machine: Invest in a reliable and precise welding machine specifically designed for upholstery work. Look for a machine with adjustable heat settings and a lightweight, ergonomic design for ease of use.

-

Welding Rods: Select welding rods that are compatible with the upholstery materials being used. Different materials may require specific types of welding rods for optimal adhesion and strength.

-

Protective Gear: Prioritize safety by using protective gear such as heat-resistant gloves, welding goggles, and a welding apron to shield against sparks and heat during the welding process.

These essential materials and tools form the foundation for successful upholstery welding, ensuring the preservation and restoration of historical upholstered pieces.

Transitioning into the subsequent section, it is essential to explore the techniques for achieving meticulous welding results.

Techniques for Upholstery Welding

Employing precision is essential for achieving impeccable results in upholstery welding. When it comes to techniques for upholstery welding, several methods are commonly used to ensure the seamless joining of materials and decorative elements.

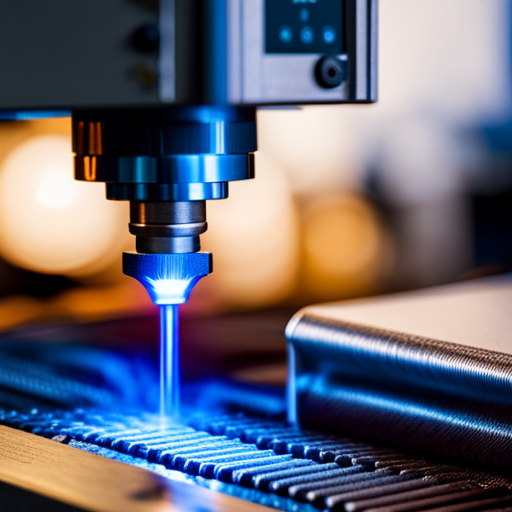

One of the primary welding techniques employed is hot air welding, which utilizes heated air to soften the thermoplastic materials, enabling them to fuse together effectively. This method is particularly useful for creating intricate designs and patterns, as it allows for precise control and manipulation of the welding process.

Additionally, high-frequency welding is often utilized for joining thicker materials or when a more robust bond is required. This technique creates a strong, airtight seal by using an electromagnetic field to excite the molecules in the materials, resulting in their fusion.

Furthermore, solvent welding is employed for materials such as vinyl, where a solvent is used to soften the surfaces, allowing them to meld together upon drying. Mastering these welding techniques is crucial for achieving the desired aesthetic and structural outcomes in upholstery restoration.

Transitioning into the subsequent section about the applications of upholstery welding in historic restoration, these refined techniques are fundamental for preserving and restoring historical upholstered pieces to their former glory.

Applications of Upholstery Welding in Historic Restoration

One crucial aspect of historic restoration projects is the application of upholstery welding techniques to preserve and refurbish upholstered pieces to their original state. The applications of upholstery welding in historic restoration are diverse and essential for ensuring the authenticity and longevity of historical furniture and decorative pieces. These applications include:

-

Repairing Damaged Upholstery: Upholstery welding allows for the precise repair of torn or damaged upholstery fabrics, ensuring that historical pieces retain their original appearance.

-

Recreating Ornate Details: Skilled welding techniques can be used to recreate intricate and ornate details on upholstered furniture, restoring them to their original grandeur.

-

Strengthening Structural Integrity: Welding can reinforce the structural integrity of historical upholstered pieces, ensuring that they can withstand the test of time while maintaining their historical authenticity.

-

Preserving Historical Aesthetics: By using welding to restore and maintain the original aesthetics of historical upholstery, the unique historical significance of these pieces is preserved for future generations.

These restoring techniques are vital for historical preservation, as they enable the conservation of valuable historical artifacts and furniture pieces for generations to come.

Moving forward, it is essential to explore the advantages of upholstery welding in preservation.

Advantages of Upholstery Welding in Preservation

In preservation, the advantages of upholstery welding lie in its ability to meticulously restore and strengthen historical upholstered pieces, ensuring their longevity and authenticity. Upholstery welding offers various restoration benefits and is considered one of the most effective preservation methods for historical upholstered furniture. The following table highlights the key advantages of upholstery welding in preservation:

| Advantages of Upholstery Welding in Preservation | Description |

|---|---|

| Structural Restoration | Welding allows for the precise repair of damaged frames and structural components, ensuring the piece retains its original form and function. |

| Authentic Material Preservation | By welding and reinforcing original materials, the authenticity of the upholstered piece is maintained, preserving its historical value. |

| Longevity and Durability | Welding strengthens weak joints and connections, increasing the overall durability of the piece and extending its lifespan. |

| Customization and Flexibility | Welding techniques offer customization options, allowing for tailored repairs while preserving the original design and aesthetic. |

| Conservation of Historical Value | Upholstery welding ensures that the historical significance and value of the piece are conserved for future generations. |

Upholstery welding, with its restoration benefits and preservation methods, plays a crucial role in safeguarding the heritage and legacy of historical upholstered furniture.

Frequently Asked Questions

What Are the Common Challenges Faced When Using Upholstery Welding for Historic Restoration Projects?

Common challenges in upholstery welding for historic restoration include techniques requiring precision due to delicate materials, safety considerations due to aged materials, and the need for specialized training and certifications to ensure preservation and quality work.

Are There Any Specific Safety Considerations to Keep in Mind When Performing Upholstery Welding in Historic Restoration?

When performing upholstery welding, specific safety precautions must be observed. This includes ensuring proper equipment requirements, maintaining temperature control, and considering material compatibility. Adhering to these measures is crucial for a safe and successful welding process.

How Does Upholstery Welding Compare to Traditional Upholstery Methods in Terms of Cost and Durability?

When comparing upholstery welding to traditional methods, cost comparison is a crucial factor. Upholstery welding may have higher upfront costs, but its longevity assessment often proves superior, providing a durable and cost-effective solution in the long run.

Can Upholstery Welding Be Used on a Variety of Historic Materials, Such as Leather, Fabric, and Vinyl?

Upholstery welding can be effectively utilized in leather restoration and fabric preservation for historic materials. The process allows for precise and durable repairs, ensuring the preservation of historical items while maintaining their original appearance and integrity.

Are There Any Specialized Training or Certifications Needed to Perform Upholstery Welding for Historic Restoration?

Specialized training and certifications are essential for mastering upholstery welding techniques. In the context of historic restoration, these credentials ensure expertise in material compatibility, safety considerations, and cost comparison with traditional methods.

Conclusion

In conclusion, upholstery welding plays a crucial role in historic restoration by preserving the integrity of original materials.

The careful selection of appropriate tools and materials, as well as the mastery of welding techniques, are essential for achieving successful restoration outcomes.

The adage ‘A stitch in time saves nine’ aptly applies to the importance of upholstery welding in maintaining the authenticity and longevity of historic upholstered furniture and decorative elements.

Dillon Hince, an expert in the realm of upholstery welding, brings a wealth of knowledge and experience to the craft. As the driving force behind nodpu.com, Dillon combines a passion for precision and creativity, offering unique insights into the art of seamlessly melding fabrics and materials. With a commitment to excellence, Dillon Hince is your go-to resource for innovative upholstery welding techniques, transforming ordinary pieces into extraordinary works of functional art.