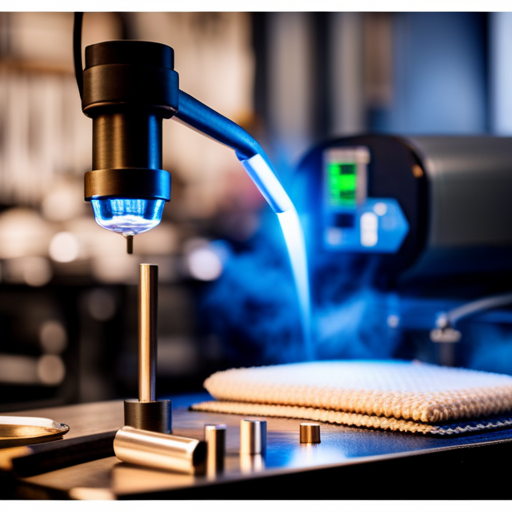

Eco-Friendly Materials for Upholstery Welding

Discover the future of upholstery welding with our innovative selection of eco-friendly materials. From recycled fabrics to natural fibers and non-toxic adhesives, we are leading the way in sustainable upholstery solutions.

This article explores the benefits of using organic cotton, hemp upholstery options, and sustainable foam alternatives.

Join us as we revolutionize the industry with environmentally conscious choices for a greener, healthier planet.

Recycled Fabrics

While traditional upholstery materials often contribute to environmental waste, using recycled fabrics offers a sustainable solution for upholstery welding. Upcycled denim and repurposed plastic are two prime examples of environmentally friendly materials that can be utilized in upholstery welding.

Upcycled denim, sourced from discarded jeans and other denim products, is a durable and stylish option for upholstery. The process of upcycling denim involves transforming old denim into new fabric, reducing the need for new materials and minimizing waste. This not only provides a second life for the denim but also reduces the environmental impact of upholstery production.

Similarly, repurposed plastic offers a sustainable alternative for upholstery welding. By utilizing plastic that has been repurposed from items such as bottles or packaging, upholstery professionals can contribute to reducing plastic waste while creating functional and attractive pieces. Repurposed plastic can be transformed into durable and weather-resistant fabrics, making it a versatile choice for upholstery applications.

Incorporating these recycled materials into upholstery welding not only reduces environmental impact but also promotes a circular economy by giving new life to discarded resources.

Natural Fibers

Natural fibers, such as cotton, linen, and hemp, offer upholstery professionals a sustainable and biodegradable option for creating environmentally conscious pieces. These materials not only contribute to a more eco-friendly approach but also provide a distinctive and natural aesthetic to the upholstery.

When working with natural fibers, upholstery professionals can further enhance their eco-friendly approach by considering the following:

-

Eco-Friendly Dyes: Utilizing natural and non-toxic dyes in the coloring process ensures that the entire upholstery production remains environmentally friendly. This approach minimizes the use of harmful chemicals and reduces the overall environmental impact of the materials.

-

Biodegradable Finishes: Applying biodegradable finishes to natural fiber upholstery ensures that the end product remains entirely eco-friendly. These finishes are designed to break down naturally over time, further contributing to the sustainability of the upholstery pieces.

-

Sustainability Practices: Upholstery professionals can also prioritize sourcing natural fibers from sustainable and ethical suppliers. This includes monitoring the production processes and ensuring that the fibers are harvested in a responsible and environmentally conscious manner.

Non-Toxic Adhesives

Upholstery professionals can further enhance their eco-friendly approach by incorporating non-toxic adhesives in the fabrication process, ensuring the overall sustainability of the upholstery welding projects.

When considering eco-friendly glue options, it’s essential to prioritize non-toxic adhesive benefits. Non-toxic adhesives are formulated without harmful chemicals, making them safe for both the environment and the individuals handling them. These adhesives contribute to improved indoor air quality, as they do not release volatile organic compounds (VOCs) that can be harmful to health and the environment.

Additionally, non-toxic adhesives are often water-based, reducing the reliance on solvent-based adhesives that can have a significant environmental impact. By choosing non-toxic adhesives, upholstery professionals can align their practices with sustainable principles while ensuring the safety of their customers and employees.

Furthermore, these adhesives can still provide the necessary strength and durability required for upholstery welding projects, dispelling any misconceptions about the effectiveness of eco-friendly adhesive options.

Incorporating non-toxic adhesives into upholstery welding processes is a crucial step towards creating a more sustainable and environmentally conscious industry.

Sustainable Foam Alternatives

Incorporating sustainable foam alternatives is essential for achieving eco-friendly upholstery welding practices. Manufacturers are increasingly turning to bio-based polymers, which are derived from renewable resources and offer durability comparable to traditional petroleum-based foams. These innovative materials not only reduce the industry’s reliance on fossil fuels but also contribute to a significant decrease in carbon emissions.

Another sustainable option gaining popularity is cork upholstery, known for its stylish appearance and eco-friendly properties. Cork is harvested from the bark of cork oak trees, a process that doesn’t harm the trees, making it a highly renewable resource. Additionally, cork’s natural properties make it resistant to mold, mildew, and pests, providing a durable and low-maintenance upholstery option. Furthermore, cork’s ability to absorb sound and shock makes it an excellent choice for upholstery applications in both residential and commercial settings.

Transitioning from traditional foam to these sustainable alternatives represents a meaningful step towards reducing the environmental impact of upholstery welding.

Moving forward, let’s explore the benefits of using organic cotton in upholstery applications.

Organic Cotton

The utilization of organic cotton in upholstery applications presents a sustainable and environmentally conscious alternative to traditional materials. Organic cotton is grown using eco-friendly dyeing processes and sustainable production methods, reducing the environmental impact compared to conventional cotton.

In organic cotton farming, soil health is prioritized through practices such as crop rotation, composting, and the avoidance of synthetic fertilizers and pesticides. These methods help maintain soil fertility and biodiversity, contributing to long-term agricultural sustainability.

Furthermore, water conservation is a key focus in organic cotton farming, with techniques such as drip irrigation and rainwater harvesting being employed to minimize water usage. By choosing organic cotton for upholstery, manufacturers and consumers can support a supply chain that values ethical and environmentally responsible practices. This not only benefits the planet but also promotes healthier working conditions for farmers and workers involved in the production process.

Hemp Upholstery Options

Continuing the focus on sustainable materials, hemp offers an environmentally friendly option for upholstery, often used in combination with organic cotton to further enhance the eco-conscious attributes of the final product.

Hemp upholstery is gaining popularity due to its numerous benefits, including:

-

Hemp Fiber Benefits: Hemp fibers are known for their strength and durability, making them an ideal choice for upholstery. The natural resistance of hemp to mold and mildew also contributes to its appeal in upholstery applications. Additionally, hemp is a highly renewable resource, requiring minimal water and no pesticides to grow, aligning with the principles of sustainable manufacturing.

-

Hemp Upholstery Durability: Hemp upholstery is highly durable, offering long-lasting performance. The robust nature of hemp fibers ensures that the upholstery can withstand regular use without compromising its structural integrity. This durability contributes to the longevity of upholstered furniture, reducing the need for frequent replacements and minimizing environmental impact.

-

Eco-Friendly Production: The cultivation of hemp requires fewer resources compared to traditional upholstery materials, resulting in a lower carbon footprint. Additionally, the biodegradability of hemp ensures that at the end of its lifecycle, the material can be disposed of without causing harm to the environment.

Frequently Asked Questions

Are There Any Potential Downsides to Using Recycled Fabrics in Upholstery Welding, Such as Reduced Durability or Color Fastness?

Reduced durability and color fastness are potential downsides of using recycled fabrics in upholstery welding. However, the environmental impact and material sourcing benefits of using eco-friendly materials should also be carefully considered in decision-making processes.

How Do Natural Fibers Used in Upholstery Welding Compare in Terms of Fire Resistance and Safety Standards?

When evaluating natural fibers for upholstery welding, fire resistance and safety standards are paramount. Natural fibers like wool and cotton may offer different fire resistance and safety profiles, warranting careful consideration for upholstery applications.

What Are Some Examples of Non-Toxic Adhesives Commonly Used in Upholstery Welding, and How Do They Perform Compared to Traditional Adhesives?

When comparing non-toxic adhesives commonly used in upholstery welding to traditional adhesives, performance is a crucial factor. It’s essential to assess their effectiveness, durability, and environmental impact. Additionally, evaluating their compatibility with natural fiber fire resistance and addressing any potential downsides of recycled fabric is important.

Are There Any Sustainable Foam Alternatives That Offer Similar Comfort and Longevity as Traditional Foam, and What Are Their Environmental Benefits?

In the pursuit of sustainable comfort, exploring foam alternatives offers longevity benefits and reduced environmental impact. Innovative materials like natural latex, soy-based foam, and recycled foam provide promising alternatives to traditional petroleum-based foam upholstery, advancing eco-friendly practices in the industry.

How Does the Cost of Organic Cotton and Hemp Upholstery Options Compare to Conventional Upholstery Materials, and Are There Any Potential Cost-Saving Benefits in the Long Run?

The cost comparison between organic cotton and hemp upholstery options versus conventional materials is crucial, considering the potential long-term cost-saving benefits and environmental impact. Evaluating the initial investment and durability is essential for informed decision-making.

Conclusion

In conclusion, eco-friendly materials for upholstery welding offer a sustainable and environmentally conscious approach to furniture production. By utilizing recycled fabrics, natural fibers, non-toxic adhesives, sustainable foam alternatives, organic cotton, and hemp upholstery options, manufacturers can reduce their carbon footprint and contribute to a more sustainable future.

Just as a patchwork quilt is made up of various pieces coming together to create a beautiful and functional whole, so too can eco-friendly materials come together to create a more sustainable and beautiful world.

Dillon Hince, an expert in the realm of upholstery welding, brings a wealth of knowledge and experience to the craft. As the driving force behind nodpu.com, Dillon combines a passion for precision and creativity, offering unique insights into the art of seamlessly melding fabrics and materials. With a commitment to excellence, Dillon Hince is your go-to resource for innovative upholstery welding techniques, transforming ordinary pieces into extraordinary works of functional art.